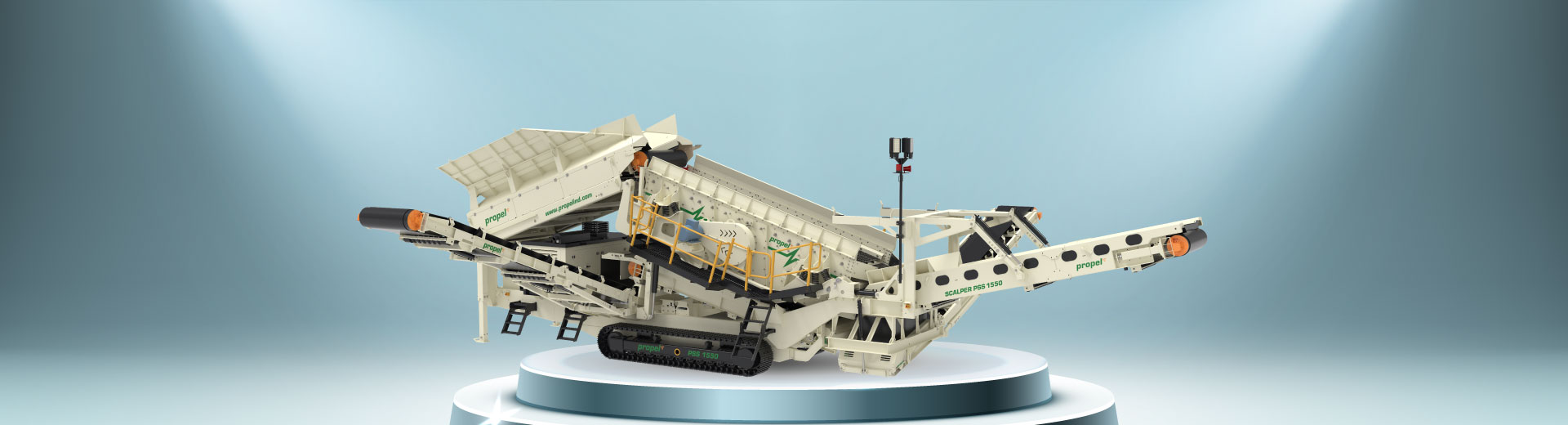

In-Depth Track Mounted Scalper (PSS 1550)

Inside-Out | October 20, 2022

Propel SCALPER PSS 1550 is a combination of extremely accurate classification of end product and high output. Its cost effectiveness is justified by its low fuel consumption, low operating and maintenance costs as well as high capacity. It has a lower carbon footprint and is environmentally friendly. Propel SCALPER PSS 1550 can be used in multiple applications such as recycling or normal aggregate pre-screening.

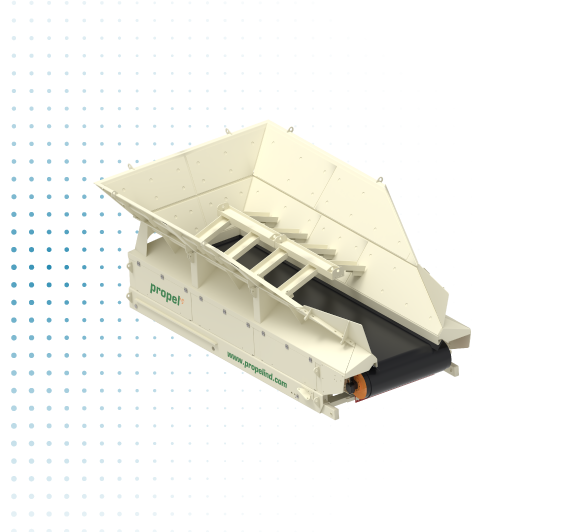

Screen

Propel Scalping Screen-1550 can be used for Primary and Secondary screening application.It has effective Screening area of 7.4 m2 in first deck and 7.2 m2 in second deck.Top deck can accommodate Grizzly bar, Punch plate and wiremesh

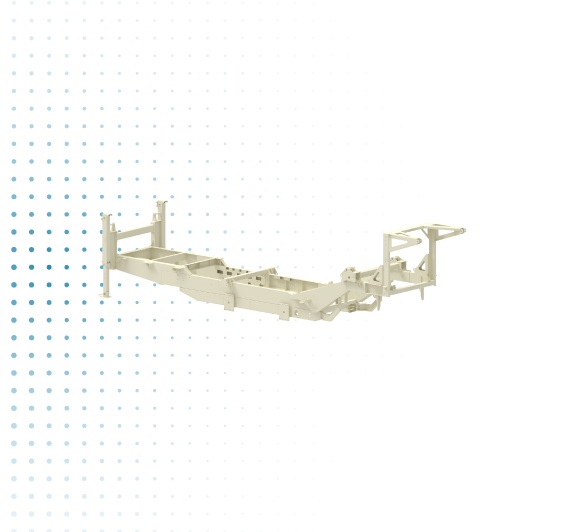

Chassis

Heavy duty C-section welded construction provides maximum strength & accessibility with spacious walkway, ladder, guard rail & hand rail ensuring safety (EHS).

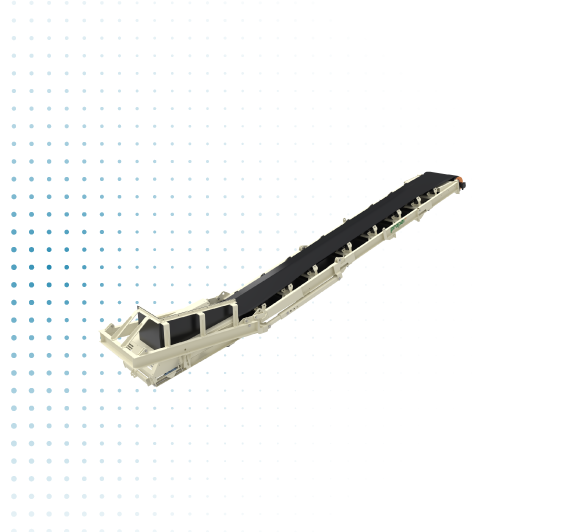

Feed Conveyor

Inclined belt feeder with hoppers and impact bars to handle large capacity of various materials is provided to feed screen.

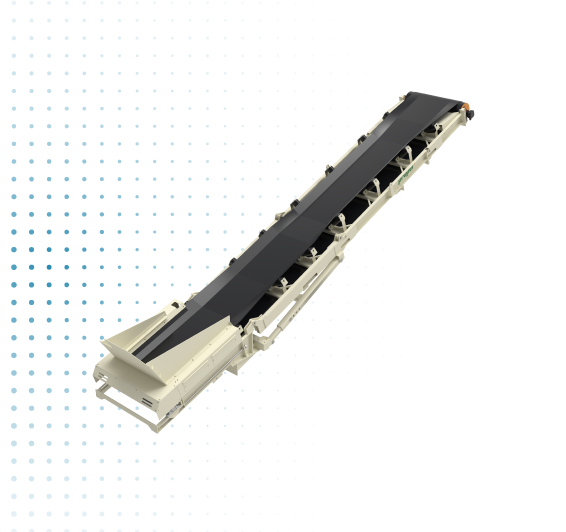

Oversize conveyor

conveyor with impact bars, handles oversized materials from the first deck and is provided with adjustable conveyor angles for easy maintenance.

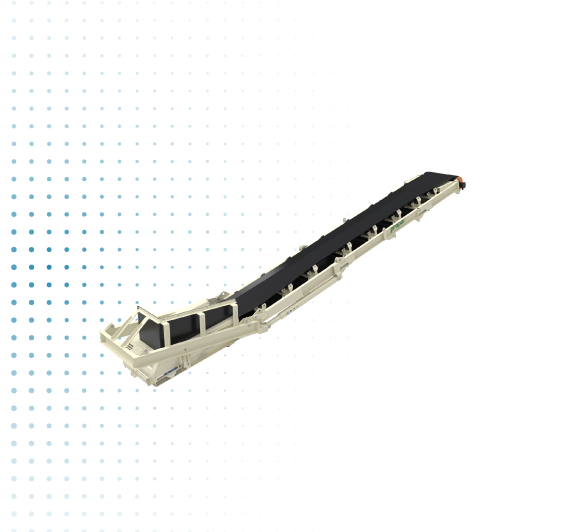

Fines Conveyor

Fines conveyor for stockpiling the screened material from second deck is adjustable with varying conveyor angles and provided with hydraulic folding system for easy transportation.

Midsize conveyor

Midsize conveyor for stockpiling the screened material from first deck is adjustable with varying conveyor angles and provided with hydraulic folding system for easy transportation.

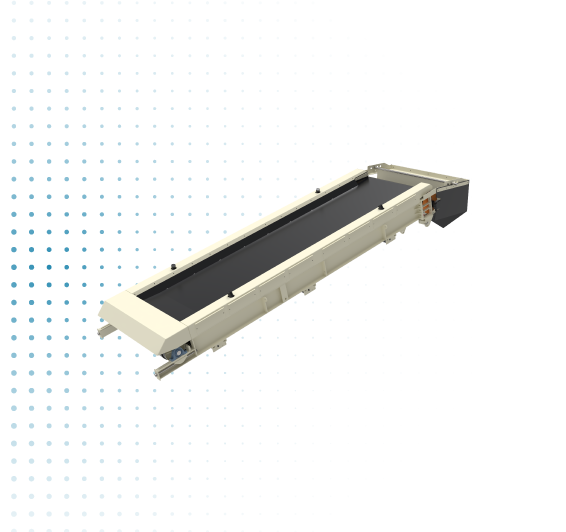

Transfer conveyor

Transfer conveyor, receives the screened material from second deck and conveys it to fines conveyor for stockpiling.

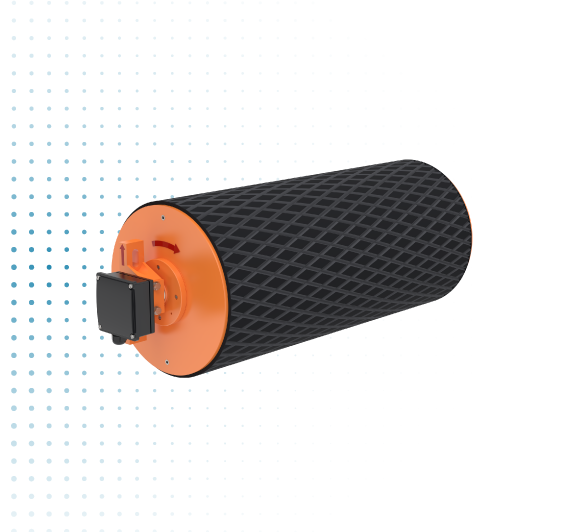

Motorized Pulley

All the conveyors are attached with motorized pulley, up to 95% of the output power produced by the motor is typically transmitted to the drum shell, consuming less space and completely free from water, dust, chemicals, grease, oil, etc.

Engine Package

The engine package consists of Engine & Alternator coupled that powers the entire equipment and safeguards from dust, noise & rain.

Diesel Tank

The diesel tank of 350 litres capacity is equipped with level indicator and filler breather, to store diesel for engine consumption.

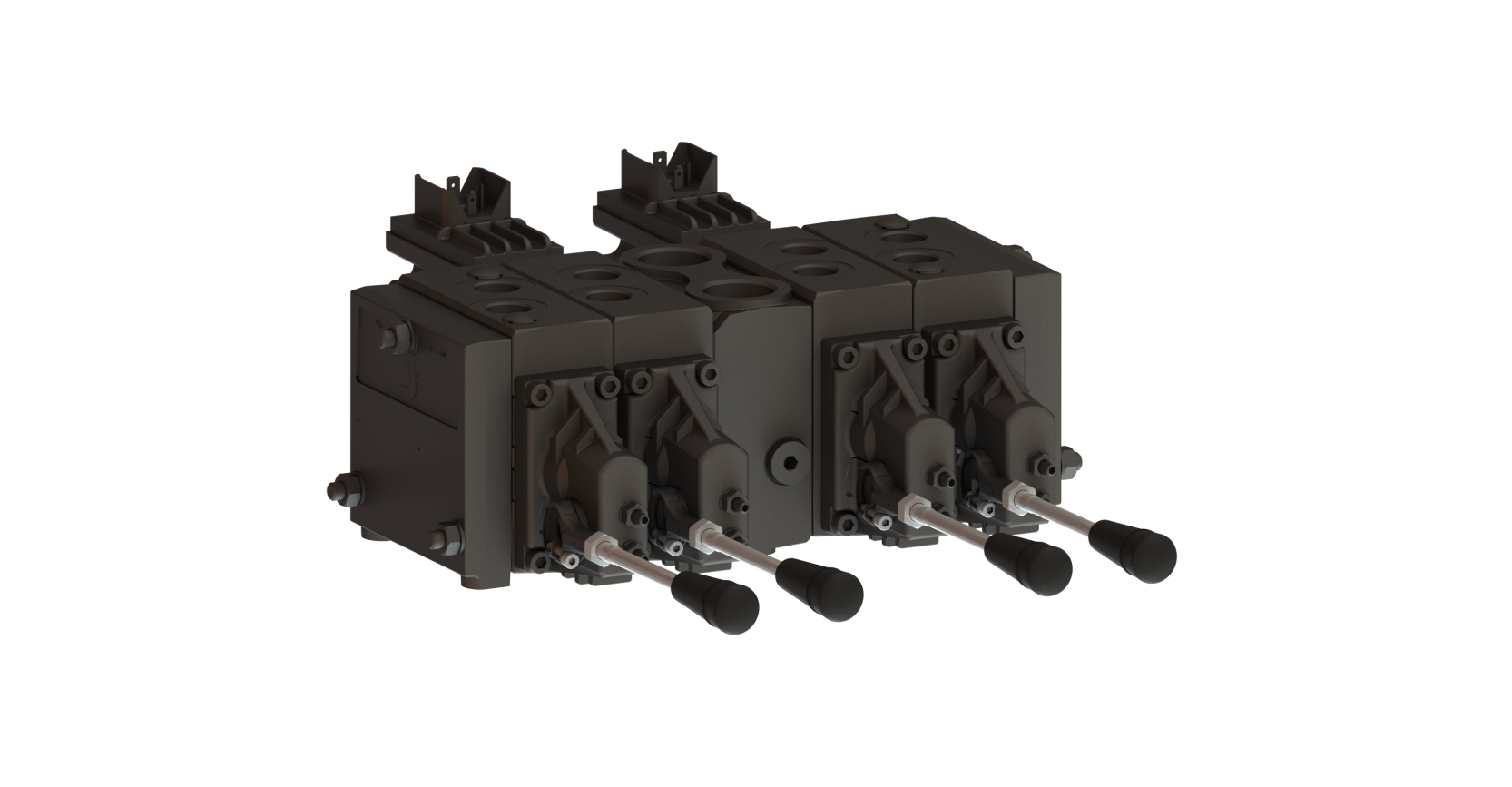

Hydraulic Control Unit

The hydraulic control unit generates and adjusts this hydraulic pressure and switches its passage. The control unit provides several pressure levels with varying priority. The line pressure control valve is governed by a solenoid and controls line pressure.

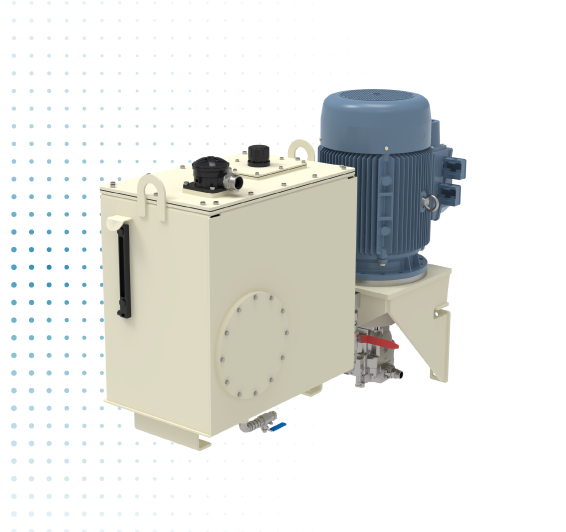

Hydraulic Power pack

The purpose of the hydraulic reservoir is to hold a volume of fluid, transfer heat from the system, allow solid contaminants to settle and facilitate the release of air and moisture from the fluid. Hydraulic tank is of capacity 300 litres.

Mechanical power is converted into hydraulic energy using the flow and pressure of a hydraulic pump. Hydraulic pumps operate by creating a vacuum to a pump inlet, forcing liquid from a reservoir into an inlet line, and to the pump. Mechanical action sends the liquid to the pump outlet, and as it does, forces it into the hydraulic system.

Undercarriage is the part of a moving vehicle that is underneath the main body of the vehicle. Crawlers are heavy-duty machines specifically developed for the transport and relocation of heavy mining equipment or processing plant equipment.

Crawler

Undercarriage is the part of a moving vehicle that is underneath the main body of the vehicle. Crawlers are heavy-duty machines specifically developed for the transport and relocation of heavy mining equipment or processing plant equipment.

Radio Remote control

Radio Remote Controller is used as application for Track Crawler moving. In radio control system, a command is transmitted from the operator to the receiver (located in the control panel). Radio signalcan transmit around 30m distance from the machine.

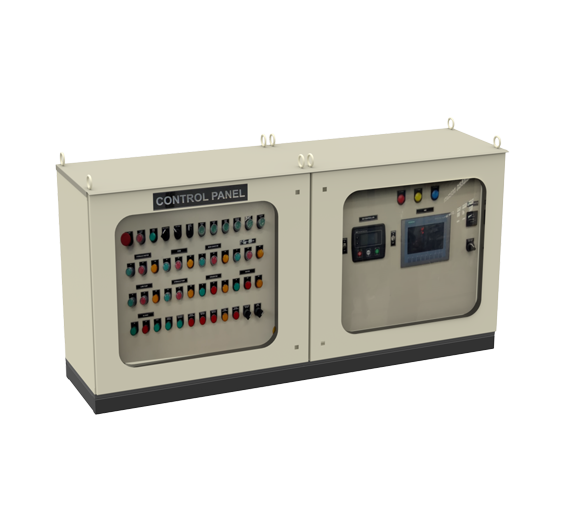

Change Over Switch Panel

Change over switch is designed to transfer electricity from the commercial power grid to a local generator when outage occurs.Also known as transfer switches, they connect directly to the generator, commercial power supply or line and have hydraulic power contactor for track movement which is controlled by control panel through control cables.

Electrical Control Panel (IP55)

Electrical control panel designed with double door arrangements (RITTAL) is dust proof and water proof with IP55 certification and is mounted in the machine. The machine is controlled by electrical operation through the operating panel. The operation has Manual Mode and Auto Mode functions, implemented through the panel by HMI display

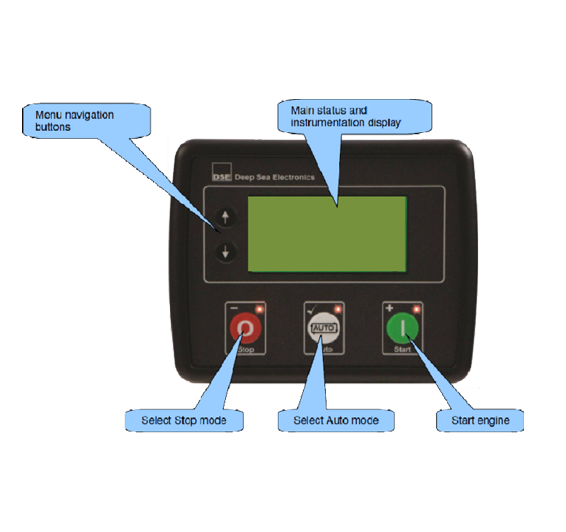

Engine Controller (DSE4520 SERIES)

Engine controller device controls the Engine Start/Stop and electrical parameters are shown in the display which are set as per our applications.