Handling high fines content material through efficient washing

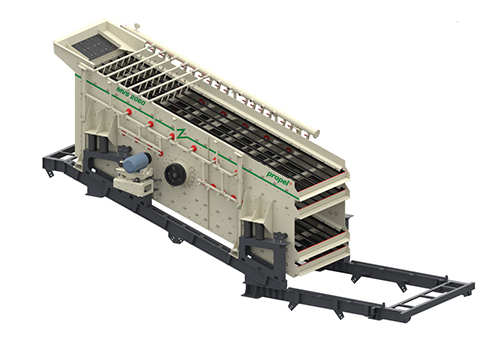

Propel Vibrating washing screen has been developed with inputs from sand producers. Size separation from 150 mm to 2.75mm happens in the vibrating screen.

Our vibrating screens are used in a variety of sizing, grading, scalping, wet screening and sand washing applications.

THE CHALLENGE

In the screening process, if fines (>50%) and moisture (>3%) contents are high in the feed, it has a marked effect on the screening efficiency. This is due to presence of clay and other sticky materials. Cleaning the screen media leads to downtime and this further affects the production of sand.

Market players were looking out for ways and means to increase the screen efficiency by washing the sand with water using the adequate pressure and volume. This kind of water screening process can eradicate sticky, undesirable material presence of clay in feed material.

Volume and pressure of water can be optimised based on the feed gradation. The nozzle orifice can be sized in the same pipe assembly to deliver different volumes and pressure of water, as per the requirement.

Depending on the size gradation in feed material, parameters are variable in our washing screens

- Speed of the machine

- Pressure of water spray

- Amplitude of machine

- Volume of water per nozzle

- Number of nozzles & its spacing

THE PROPEL SOLUTION

To overcome this challenge, Propel introduced the integrated isolated washing system within the circular motion - inclined screen equipment.

SPEED OF MACHINE

High speed of machine (i.e. above 900 rpm) and low stroke of machine (6-7mm) allow the material to stratify with high efficiency to separate fines from the coarse size materials.

SPRAY NOZZLES

Nozzles perform well under high or low pressure in range of 0.5 to 5 bar. The nozzle gives the sharply defined 90° flat jet providing efficient material washing. As sufficient water volume and spray pressure ensures good sand quality and high separation efficiency of washing screen, customers are glad with our solution.