Breakthrough in Tertiary Crushing AVRC 1300 Roll Crusher at LSC Infratech Ltd

Introduction1

LSC Infratech Ltd., based in Rudrapur, Uttarkand, has been a leader in supplying high-quality stone aggregates across India for over 33 years. With 10 plants in three states and six branches, LSC produces 30,000 metric tons of stone aggregates daily, including silica sand and manufactured sand

Successful Collaboration with Propel Industries

LSC’s remarkable success goes hand in hand with their long 12-year collaboration with Propel Industries. The performance, reliability, and service support of Propel’s crushing and mining equipment play a vital role in LSC’s growth, with multiple deployments across their operations.

Challenge: In Silica Sand Manufacturing

LSC faced issues of high operating costs in their silica sand manufacturing process, which involves tertiary crushing of very abrasive rock under small-sized feed conditions. They found conventional tertiary crushing solutions were plagued with issues like high operational costs, poor reliability, and frequent maintenance. So they asked Propel to develop an efficient and reliable tertiary crushing system.

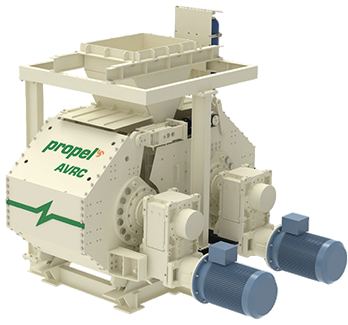

Solution: Development of the Innovative Roll Crusher AVRC 1300

Propel Industries has made substantial investments in research and development to create an innovative roll crusher that excels in capacity, performance, and reliability while offering the added advantage of lower operating costs, surpassing global standards.

At the LSC crushing plant, the product AVRC 1300 delivered exceptional performance and exceeded the expectations of the customer.

Key Features of AVRC1300

At LSC, we have always focused on adopting newer technology and reducing our operating cost. We are using Propel Roll Crusher for production of very good quality silica sand. The main advantage of this Roll Crusher lies in the low operating cost, or rather I should say, very low operating cost. It has a very low wear cost, low power cost and hardly any daily maintenance.

Customer Satisfaction and Endorsement

Saurabh Agarwal, Director of LSC Infratech Ltd., emphasizes the longstanding and successful partnership with Propel, spanning over 12 years. He attributes their continued collaboration to Propel's unwavering commitment to continuous innovation, reliable, high-quality products meeting global standards, and exceptional service.

He mentions that team LSC is very happy with the performance of Propel’s Roll Crusher AVRC 1300. This advanced solution has significantly reduced their operating costs, optimized silica sand production, and delivered superior quality with high product output.

| Reduced Operating Costs | Enhanced Operational Efficiency & Safety | Superior Production & Quality |

|---|---|---|

| Significantly lower power consumption | Modern Design no flywheels & belts | High Throughput capacity (50 to 150 TPH) |

| Lower wear costs | Improved safety & reduced noise | Produces superior-quality silica sand |

| Continuous operation upto>20hrs per day | Integrated motors with a reduced gearbox for smooth, quiet operation | High product yield |

| Minimal maintenance | Cubical shaped sand produc | |

| Hydraulic cavity clearing | Meets Zone 2 BIS standards |

LSC Infratech Ltd., confirms that AVRC1300 will have a transformative impact in the tertiary stage crushing domain, where sand making or fine crushing is required. This equipment stands out as an ideal choice due to its significantly lower wear and power costs compared to VSI and cone crushers & ability to process small size feed material efficiently.

CLICK HERE:Brochure

2025 PROPEL INDUSTRIES © All Rights Reserved

Design & Developed by AGT