What and why of Vibro motor?

Productivity Enhancement | December 14, 2020

A Vibro motor is an electric induction motor with an unbalanced mass mounted on both ends of its shaft. This unbalanced mass generates a mechanical vibration which in turn causes the equipment to vibrate.

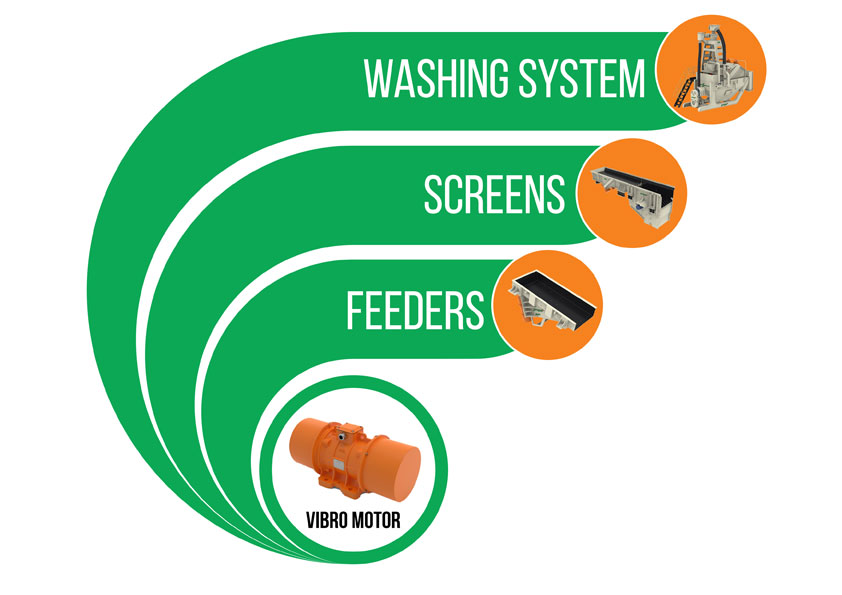

The Vibro motor, which is also referred to as external electric vibrators or unbalanced motors helps to feed screen, convey, separate, Sizing, empty, dose, loosen, clean, compact, etc., and so, is used in various sectors.

A vibro motor is used in

- Mining

- Fertiliser

- Chemical

- Pharma

- Food industry

Not one but two…..

Propel Industries uses vibro motors for aggregates handling application and this demands the use of a pair of vibro motors.

While a single vibro motor can generate only circular vibration, a pair leads to linear or rectilinear vibration.

How do we choose the speed/ RPM for the equipment?

| Speed in RPM | Vibration type Circular / Linear | Vibration Stroke range in mm | Application area |

|---|---|---|---|

| 960 | Linear | 6 - 11 | Feeding/ Separation / Screening / Sizing / Sieving |

| 1440 | Mostly Linear | 2.8-5.2 | De-watering / Bin activators |

| 2880 | Circular | 0.6 – 1.6 | Concrete consolidation/ Silo / hopper emptying/Slackening |

Remember

- Never use two different brand motors within a pair. This is because even a minute difference in performance can lead to difference in speed/rpm between the paired motor. The mounting holes may not match.

- Any difference in speed between the motors can impact the performance of the equipment. It may also lead to the overheating of the motor.

Common failures and how to prevent it

| Failures | Causes/ Consequences | Prevention |

|---|---|---|

Bearing failure |

Jamming of rotor/rubbing of rotor with the stator. This in turn leads to motor coil overload and it gets burnt |

Periodic inspection of the bearing and subsequent lubrication. Preventive replacement of bearings once the recommended shelf life is surpassed.

|

Breaking of mounting bolts/mounting leg of motor |

Uneven bolt torque/tightening and uneven mounting surface can lead to this condition |

Always check for uniform torque on all the bolts as per OEM recommendation. Ensure that the mounting surface is flat and uniform. After installation, check the torque and re-tighten the bolts after few hours of operation. |

Maintenance tips

- It is important to ensure that the mounting surface is flat and smooth during installation

- Tightening the mounting bolts with uniform torque, as recommended by the manufacturer, is important

- Remember to connect both the motors through the same power distribution points.

- The tightness of the mounting bolt must be checked after few hours of operation.

- The eccentric weight setting must be identical on both sides of the motor. It is a best practice to keep the eccentric weight setting below 85%

- The vibro motors should not be operated with the covers open. Lubrication should be done as per schedule and with the correct lubricant, as per the recommendations of the manufacturer.

- The bearings at both the ends are loaded unevenly and the wear is also uneven in positions other than horizontal mounting. Periodically inverting/inter-changing the motor position will help distribute the wear evenly and enhance the life of the motor.

- Any abnormal noise is an indication of poor lubrication and worn-out bearing. Check the bearing temperature, take corrective action to prevent major failure.