Track Mounted Vertical Shaft Impactor TMV 200

Inside-Out | December 8, 2021

The track-mounted vertical shaft impactor has an established track record of cost savings, durability and unmatched performance.

The track mounted VSI 200 is made up of the following parts –

- Vertical Shaft Impactor

- Feed conveyor

- Metal detector

- Telescopic assembly

- Chassis and walkway

- Main conveyor

- Motorised pulley

- Engine pack

- Diesel tank

- Hydraulic control unit

- Hydraulic power pack

- Crawler

- Radio remote control

- Change over switch/VFD panel

- Electrical control panel (IP55)

- Engine controller ( DSE4520 series)

Here is a close look at each of the components.

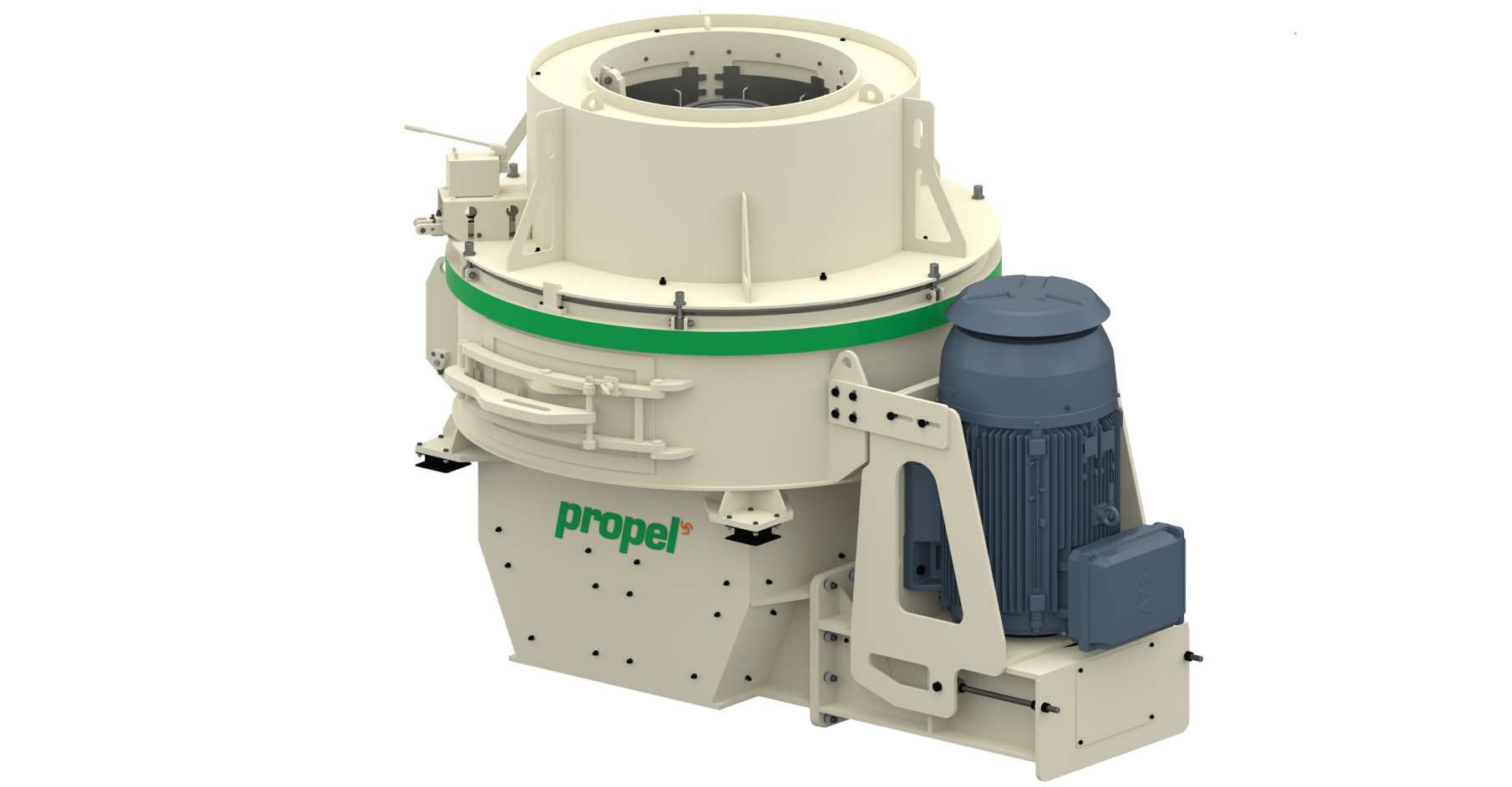

Vertical Shaft Impactor

Propel Vertical Shaft Impactor has been developed with inputs from aggregate producers. The high velocity impact crusher in Propel VSI enhances the shape of the aggregates and improves the surface structure. It is suitable for all types of materials.

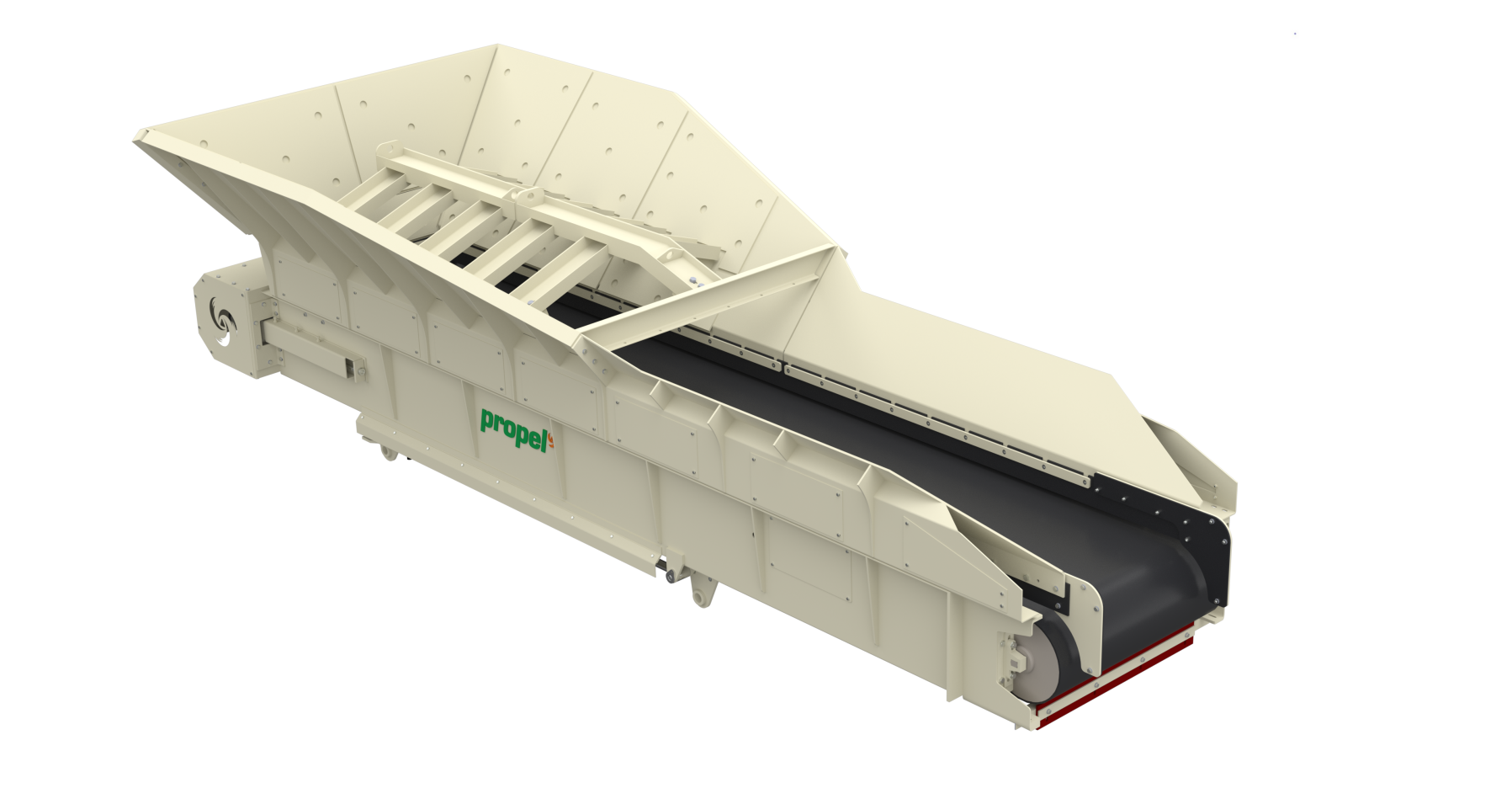

Feed Conveyor

The feed conveyor of the Track VSI is responsible for transferring material from secondary crusher to the VSI. The conveyor consists of liners bolted upon hoppers made up of sail hard, replaceable rock box arrangement, motorized pulley and metal detector.

Metal detector

The metal detector system 3000 is designed to detect both medium and large pieces of metal. It can also adjust the sensitivity. The metal detector consists of an amplifier and an inductive detector coil. This prevents the metal pieces from entering the crusher. It rings an alarm and stops the feeding conveyor.

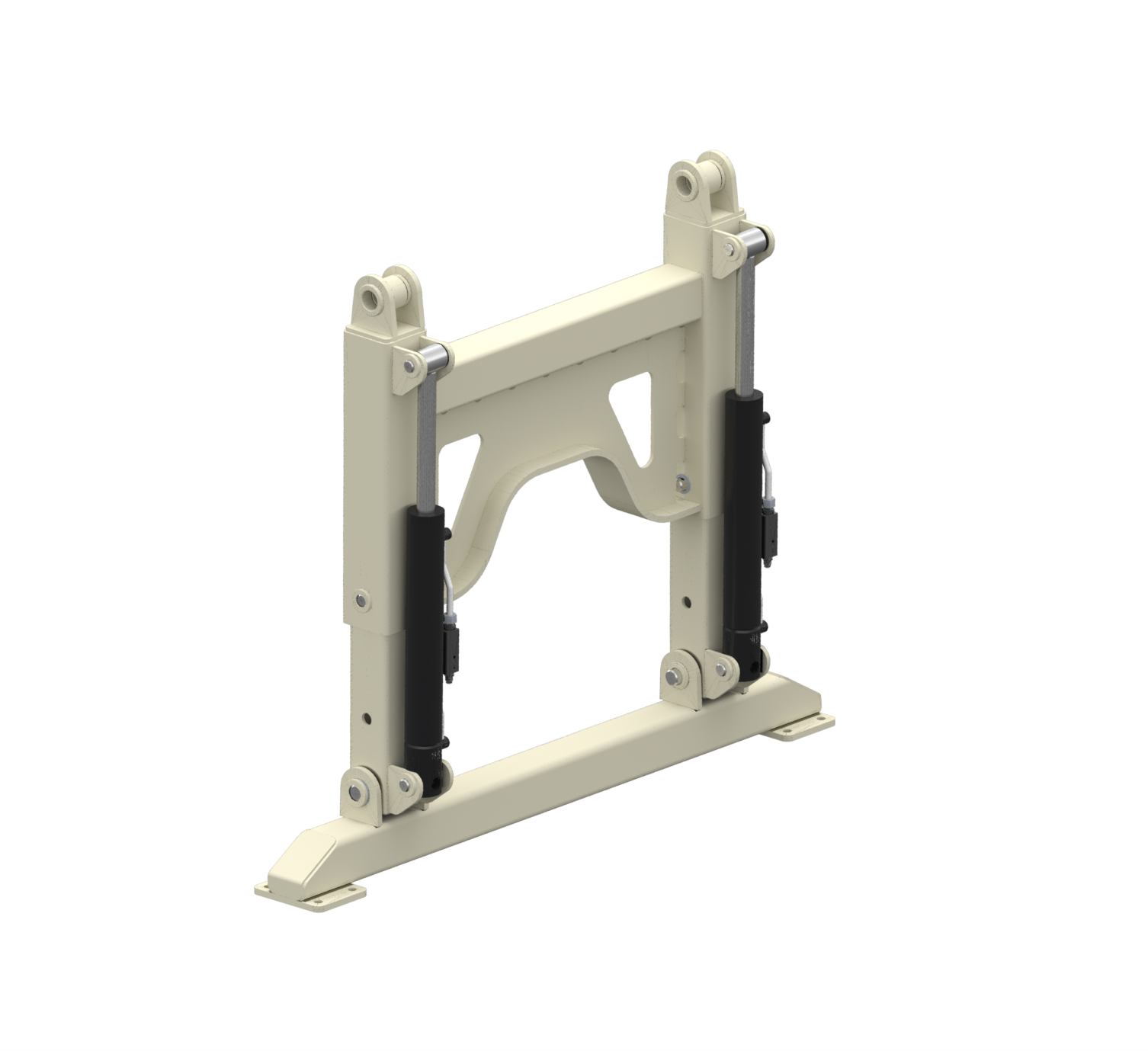

Telescopic Assembly

The Telescopic assembly is designed to lower the equipment for transportation and also to lift it hydraulically for operation and crusher maintenance

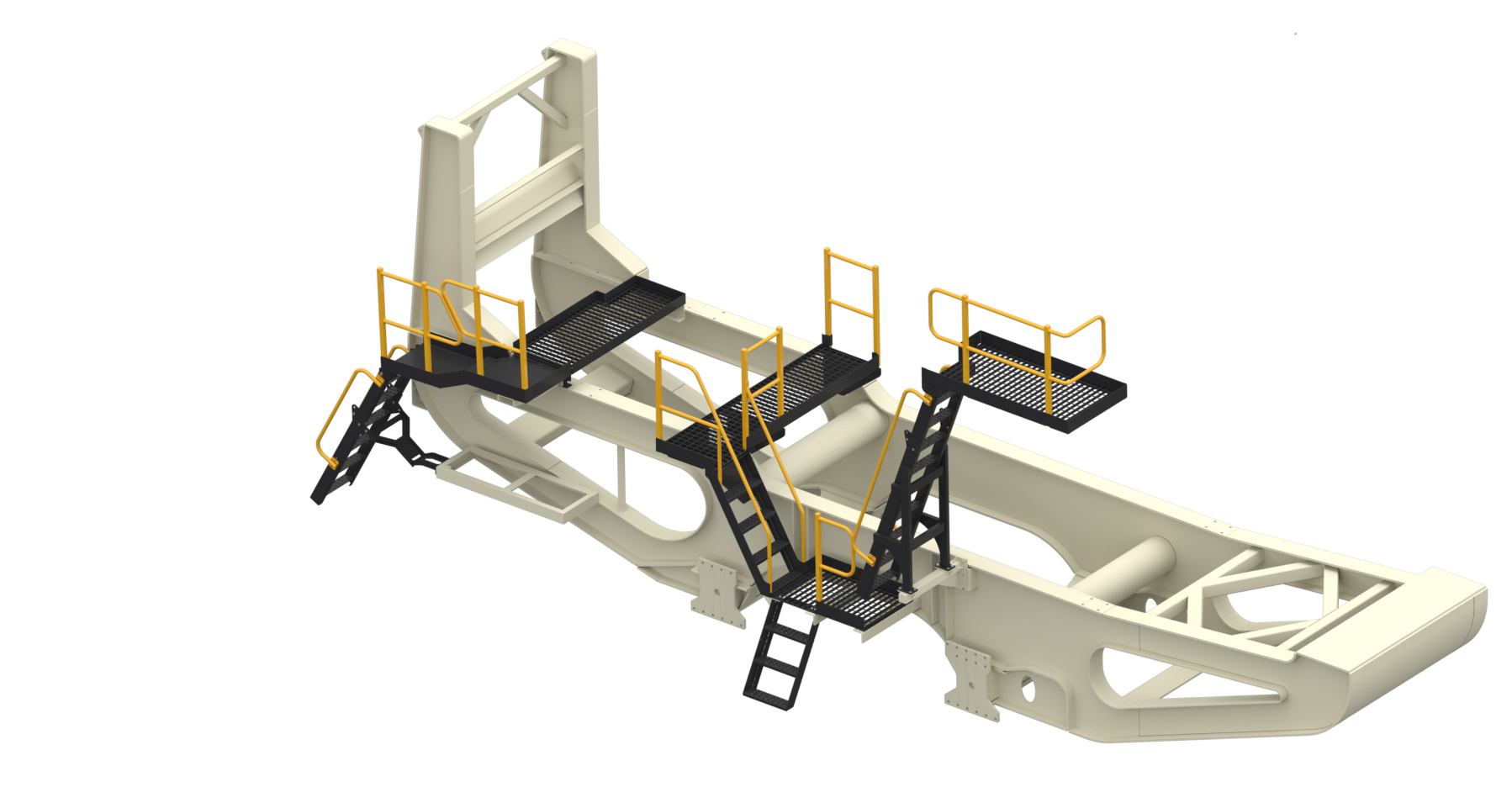

Chassis & Walkway

Heavy duty I-section welded construction provides maximum strength and accessibility to the equipment. The design includes spacious walkway which increases accessibility.

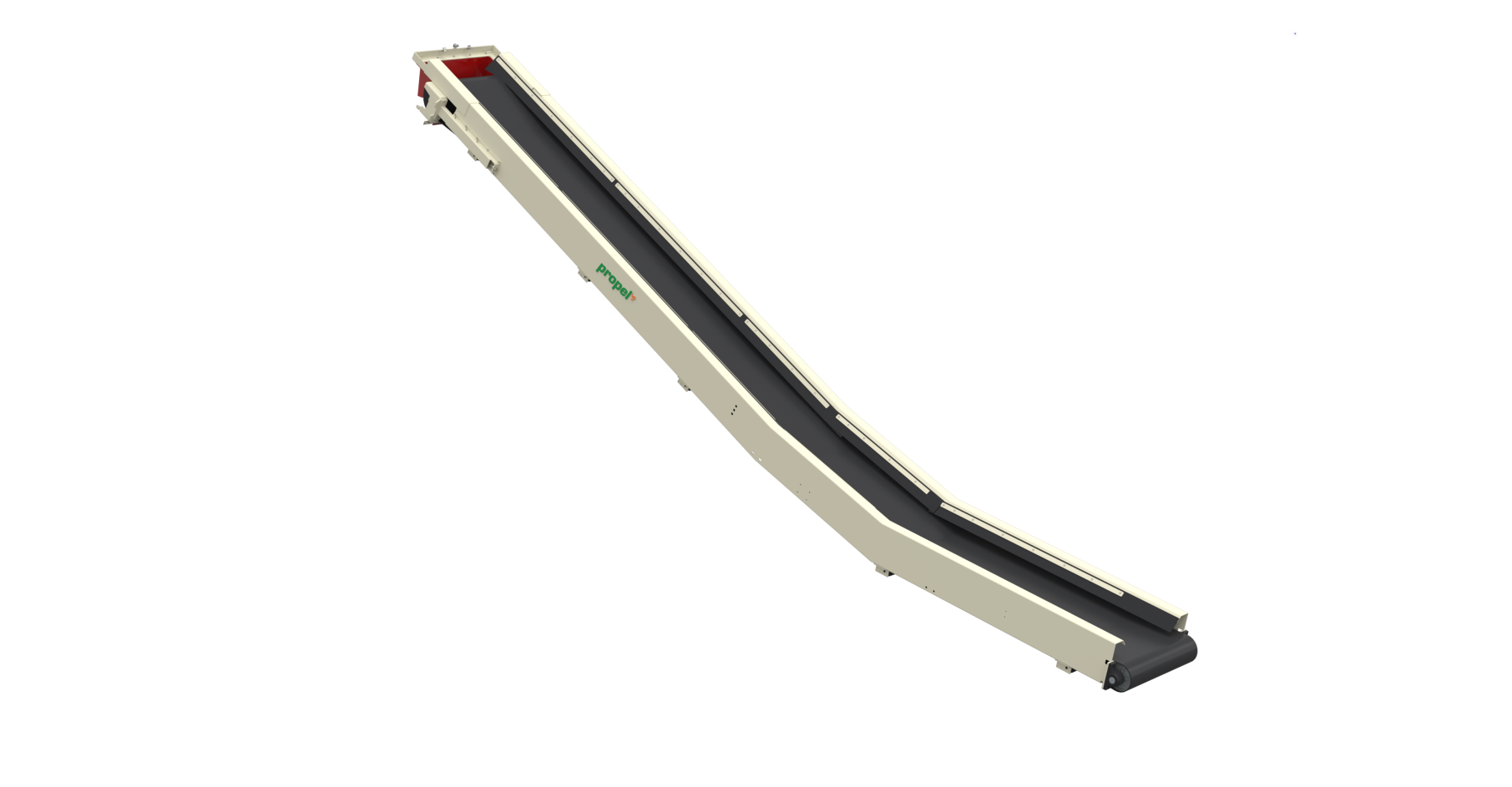

Main Conveyor

The main conveyor is responsible for conveying material from VSI to next stage plant. It consists of a motorized pulley, nip guide and a dust suppression system.

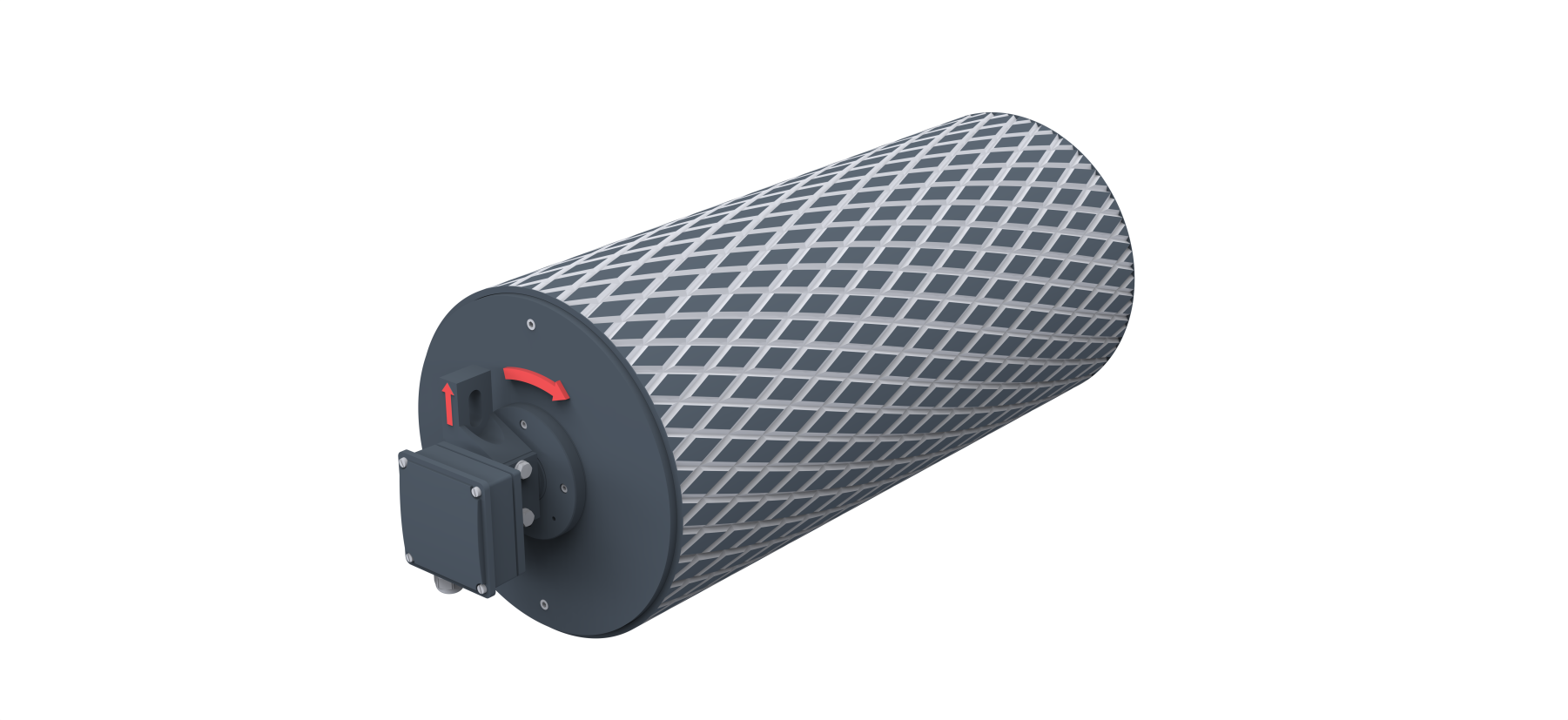

Motorized Pulley

Both the main conveyor and feed conveyor are attached to the motorized pulley. Up to 95% of the output power produced by the motor is typically transmitted to the drum shell and it consumes lesser space and is completely protected from water, dust, chemicals, grease, oil, etc.

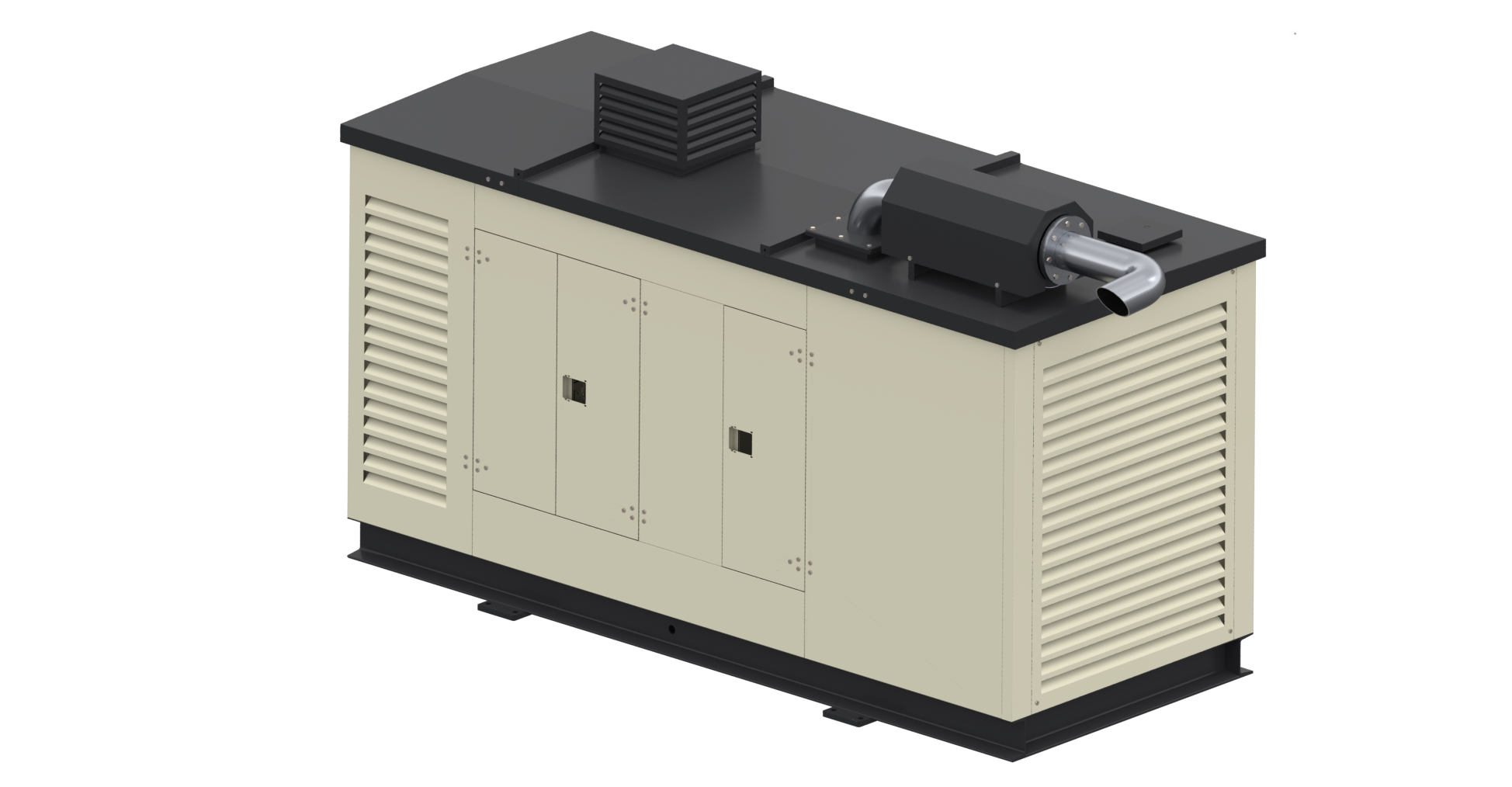

Engine Package

The engine package consists of an Engine and an alternator. This couple powers the entire equipment and safeguards from dust, noise and rain.

Diesel Tank

The diesel tank is used to store diesel for engine consumption. It is equipped with level sensing and a filler breather. The capacity of the diesel tank is 800 litres.

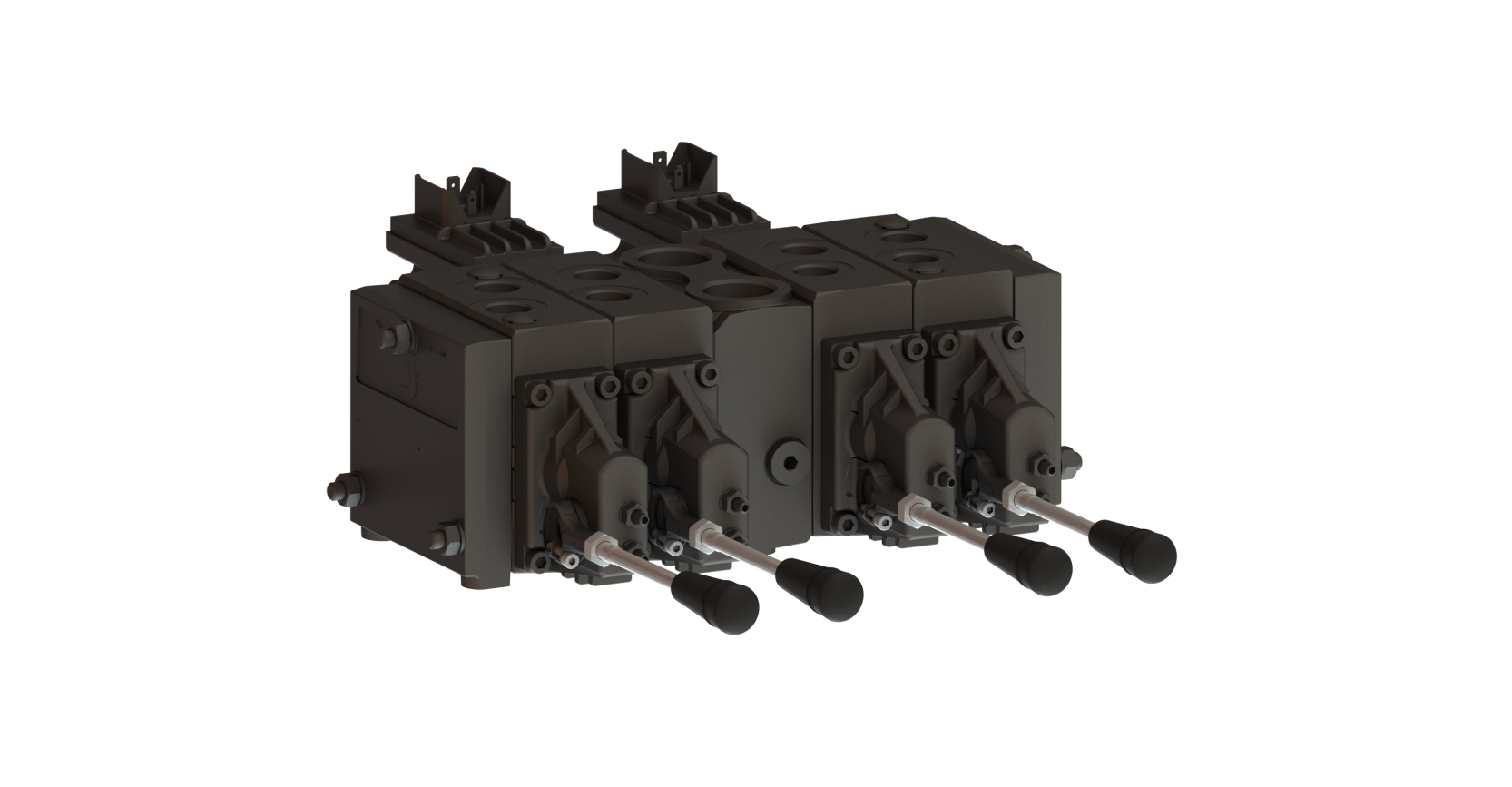

Hydraulic Control Unit

The hydraulic control unit generates and adjusts the hydraulic pressure and switches its passage accordingly. The control unit provides several pressure level options. The line pressure control valve is governed by a solenoid and controls the line pressure.

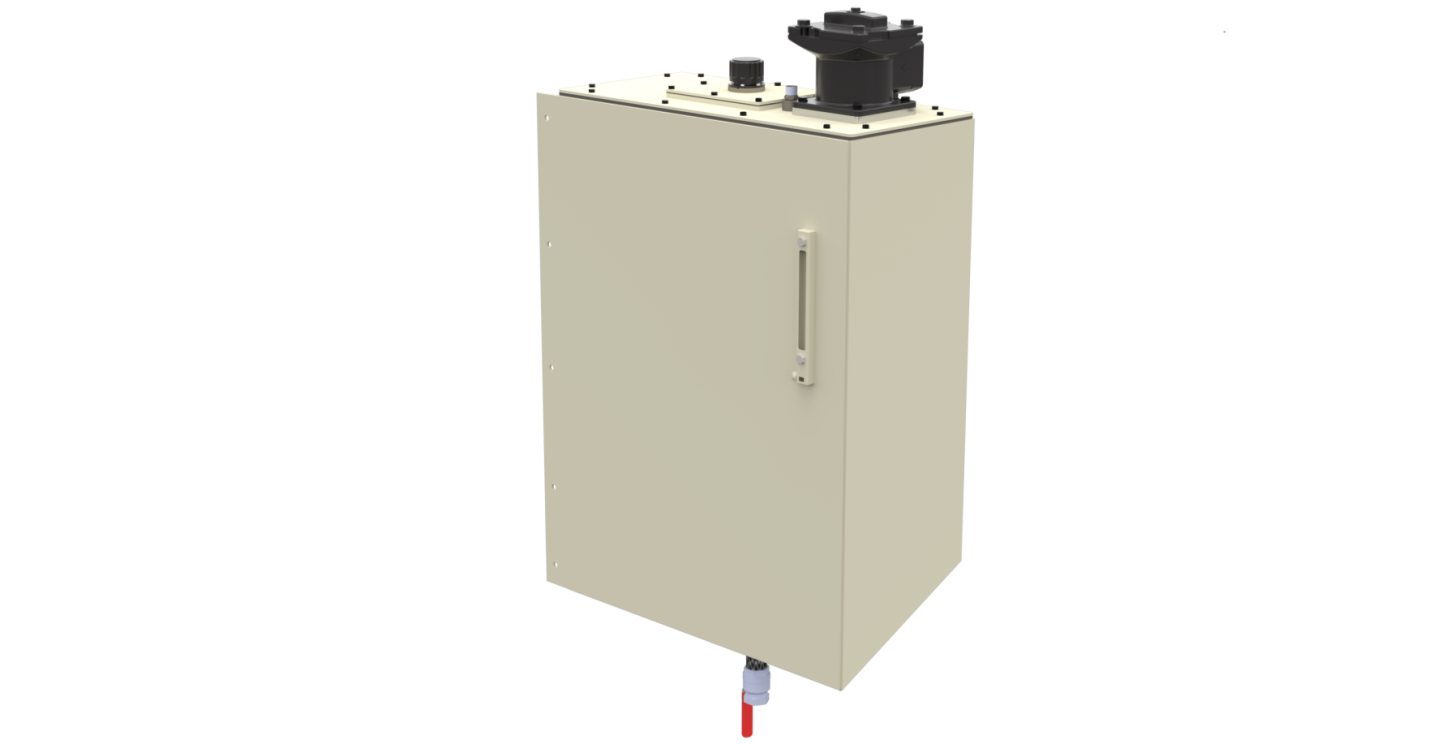

Hydraulic Power pack

The purpose of the hydraulic reservoir is to hold a volume of fluid, transfer heat from the system, allow solid contaminants to settle down and to facilitate the release of air and moisture from the fluid. The capacity of the hydraulic tank is 400 litres.

Crawler

The undercarriage is the part of a moving vehicle that is underneath the main body of the vehicle. Crawlers are heavy-duty machines specifically developed for the transportation and relocation of heavy mining equipment or processing plant equipment

Radio Remote control

The radio remote controller is used as application for track crawler movement. In Radio control system, when a command is transmitted from the operator to the receiver (located in the control panel), radio signal is transmitted to around 50m distance from the machine.

Change Over Switch/VFD Panel :

This panel is designed for power changeover and it controls the equipment motor based on VFD (variable frequency drive).

IP55 VFD is attached to the equipment motor and the heat dissipation cooling fan is part of the panel.

Electrical Control Panel (IP55)

The electrical control panel is designed with double door for making it dust proof and water proof with IP55 certification and is mounted on to the machine. The machine is controlled by electrical operation via the operating panel.

It can be operated through both manual and auto mode, implemented through the panel

While the manual operation happens through illuminated push bottons, auto mode operation is controlled by the HMI display.

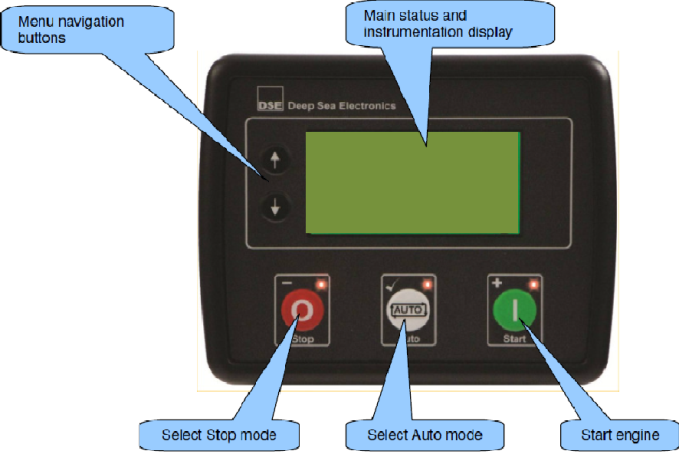

Engine Controller (DSE4520 SERIES)

The engine controller device helps to start or stop the engine. The electrical parameters, which have been set as per applications, are shown on display.