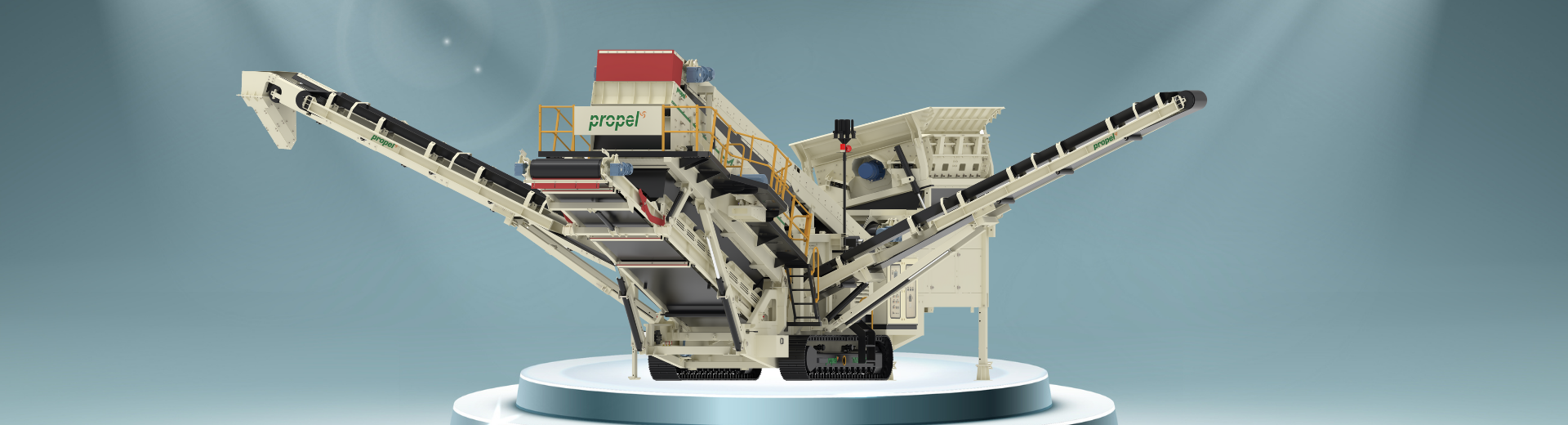

In-depth – Track Mounted Screen 1561 (3Deck)

Inside-Out | December 8, 2021

Propel electrical mobile screens’ robust design, versatility and easily adjustable strokes make it suitable for multiple applications

The track mounted screen TMS 1561 is made up of the following parts –

- Screen

- Chassis

- Vibrating Grid/ Tipping Grid

- Feed Conveyor

- Main Conveyor

- Chutes and Side Conveyors

- Over Size Conveyor

- Tail Conveyor

- Motorised pulley

- Engine package

- Diesel tank

- Hydraulic control unit

- Hydraulic power pack

- Crawler

- Radio remote control

- Change over switch panel

- Electrical control panel (IP55)

- Engine controller ( DSE4520 series)

Let us now delve into the key aspects of each component.

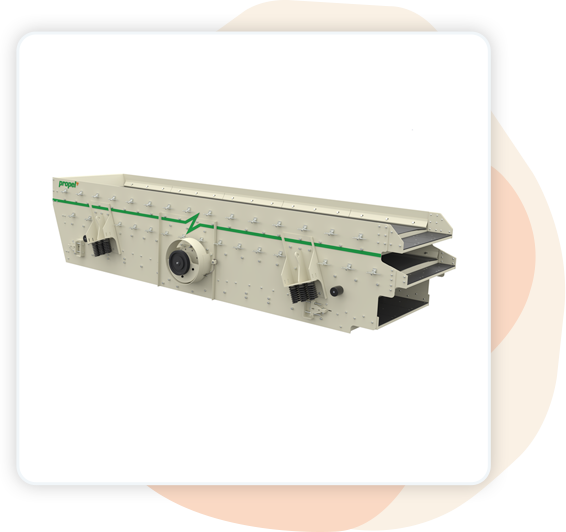

Screen

Propel Vibrating screen 1561 handles the materials in effective screening area of 8.5m2 in each deck with maximum size up to 150mm. It creates circular motion with two-bearing oil lubricated exciter assembly.

Its bottom deck with end tensioning deck frame design replaces the wire mesh.

Chassis

Heavy duty I-section welded construction provides maximum strength and accessibility.

Vibrating grid and Tipping grid

Vibrating Grid

Tipping Grid

The vibrating grid and tipping grid is responsible for transferring materials of size less than 100 mm to the feed conveyor. Materials greater than 100 mm are not allowed into the screen.

While the tipping grid is a stationary structure, the vibrating grid produces vibrations so that the materials are screened effectively without jamming.

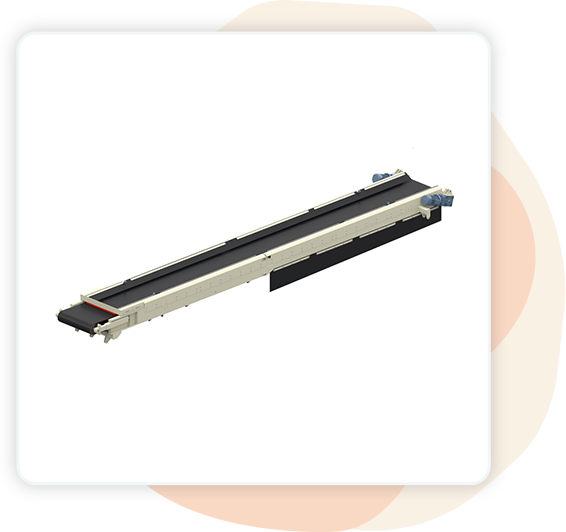

Feed conveyor

The feed conveyor conveys materials that are passed through vibrating grid/tipping grid to the main conveyor.

Main Conveyor

The main conveyor is responsible for conveying materials from feed conveyor to screen 1561.

Chutes and Side conveyors

Chutes are responsible for transferring materials from screen discharge end to their respective conveyors. There are three chutes - Oversize chute, left-hand side (L.H.S) & right-hand side (R.H.S) chutes.

The side conveyors convey the materials from screen to the second and third deck as an end product.

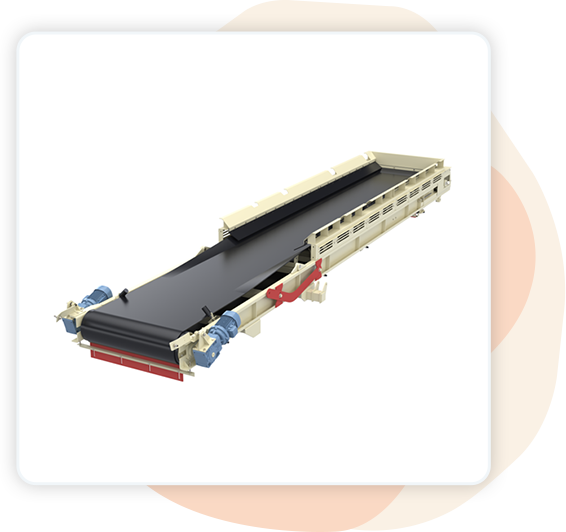

Oversize conveyor

The oversize conveyor conveys the materials from screen first deck to cone crusher/ VSI equipment for recycling purpose.

Tail conveyor

The tail conveyor conveys fine materials as the end product.

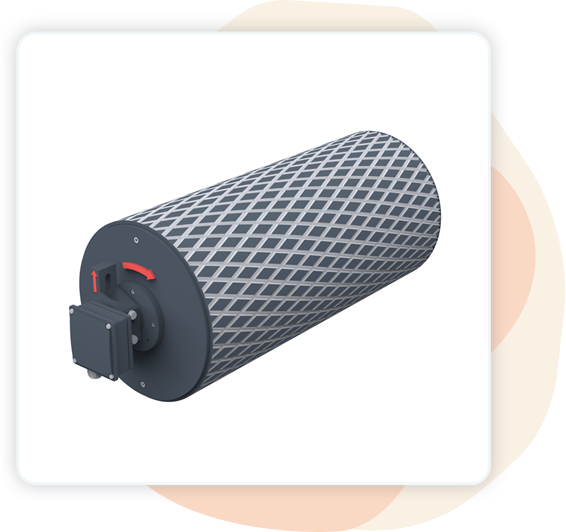

Motorized Pulley

All conveyors are attached with motorized pulley. Up to 95% of the output power produced by the motor is typically transmitted to the drum shell. It consumes less space and is completely protected from water, dust, chemicals, grease, oil, etc.

Engine Package

The engine package consists of the engine and alternator coupled to power the entire equipment.

This safeguards the unit from dust, noise and rain.

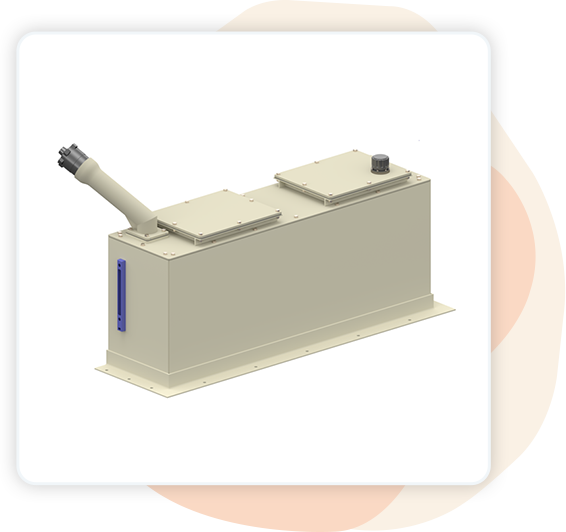

Diesel Tank

The diesel tank is used to store diesel for engine consumption.

It is equipped with level sensing and a filler breather.

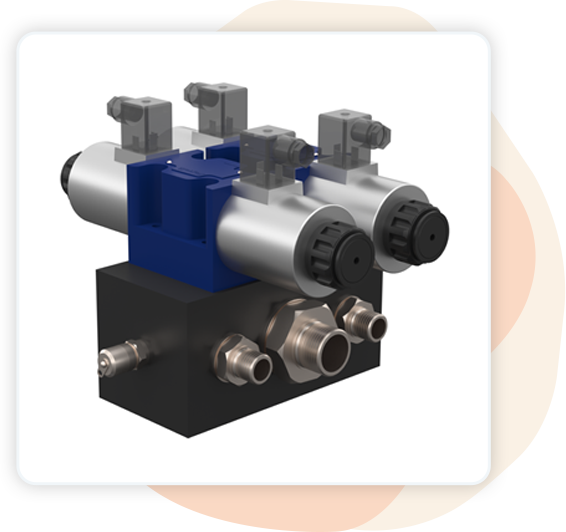

Hydraulic Control Unit

The hydraulic control unit generates and adjusts the hydraulic pressure and switches its passage. The control unit provides several pressure levels. The line pressure control valve is governed by a solenoid and it controls the line pressure.

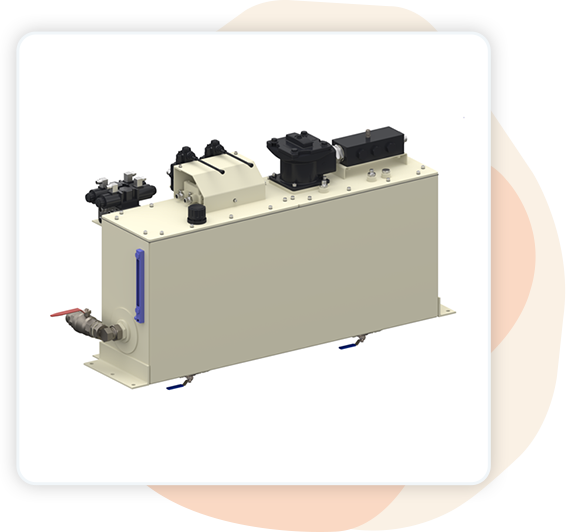

Hydraulic Power pack

The purpose of the hydraulic reservoir is to hold a volume of fluid, transfer heat from the system, allow solid contaminants to settle down and also, facilitate the release of air and moisture from the fluid. The capacity of the hydraulic tank is 400 litres.

Crawler

The undercarriage is the part of a moving vehicle that is underneath the main body of the vehicle. Crawlers are heavy-duty machines specifically developed for the transportation and relocation of heavy mining equipment or processing plant equipment.

Radio Remote Controller

The radio remote controller is used as application for track crawler movement. In radio control system, when a command is transmitted from the operator to the receiver (located in the control panel), radio signal transmit to around 50m distance from the machine.

Change Over Panel

The change over panel gives the flexibility to power the plant either by external electric connection or by on-board diesel generator power pack unit. This dual power mode is an optional feature.

Control Panel

The electrical control panel has been designed with a double door to ensure it is dust-proof and water-proof.

It comes with IP55 certification and is mounted on to the machine, which is controlled by the electrical operation via the operating panel. The manual mode and auto mode functions are available in the panel.

While the manual operation becomes possible through illuminated push buttons, auto mode operation is controlled by HMI display.

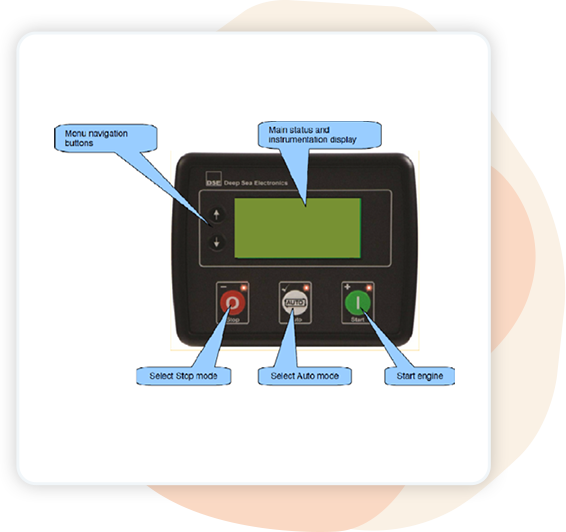

Engine Controller (DSE4520 SERIES)

The engine controller device is used to start or stop the engine. The electrical parameters are shown in the display, which have been set as per applications.