IN DEPTH – Track Mounted Cone Q250

Inside-Out | August 12, 2021

Propel TMC Series feature a unique combination of crusher speed, throw and cavity design. This combination is known for its revolutionary higher capacity and better product quality. It has been designed to ensure trouble-free operation in heavy and continuous applications.

What makes Propel TMC series special?

Unique combination of crusher speed, throw and cavity design which leads to higher capacity and better product quality.

Unique combination of crusher speed, throw and cavity design which leads to higher capacity and better product quality.  Ensures trouble-free operation in heavy and continuous applications

Ensures trouble-free operation in heavy and continuous applications

These are the main features of Propel track series. These features have been validated by our customers.

The track mounted cone Q250 is made up of the following parts:

Cone crusher

Cone crusher  Feed conveyor

Feed conveyor  Metal detector

Metal detector  Telescopic assembly

Telescopic assembly

Chassis and walkway

Chassis and walkway  Main conveyor

Main conveyor  Motorised pulley

Motorised pulley  Engine pack

Engine pack

Diesel tank

Diesel tank Hydraulic control unit

Hydraulic control unit  Hydraulic power pack

Hydraulic power pack  Crawler

Crawler

Radio remote control

Radio remote control  Change over switch panel

Change over switch panel Electrical control panel (IP55)

Electrical control panel (IP55)  Engine controller ( DSE4520 series)

Engine controller ( DSE4520 series)

Let us now understand the key aspects of each component.

Cone Crusher

Propel QM series Cone Crushers combine the best power utilization per cone diameter, cavity design of higher density, optimized crusher speed and efficient throw.

The higher cavity density improves the inter-particle crushing action.

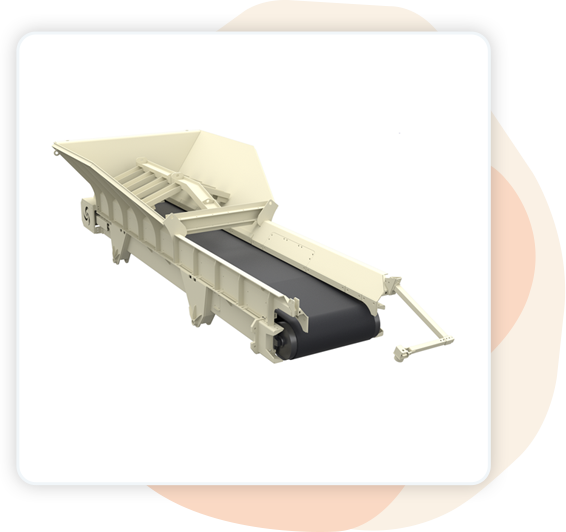

Feed Conveyor

The feed conveyor of Track Cone is responsible for transferring material from the jaw crusher to the cone crusher. The conveyor consists of hoppers plates made up of hardox 400, replaceable rock box arrangement, nip guide, motorized pulley, metal detector and cone feed level sensor. Slider bed roller system is used for preventing material spillage.

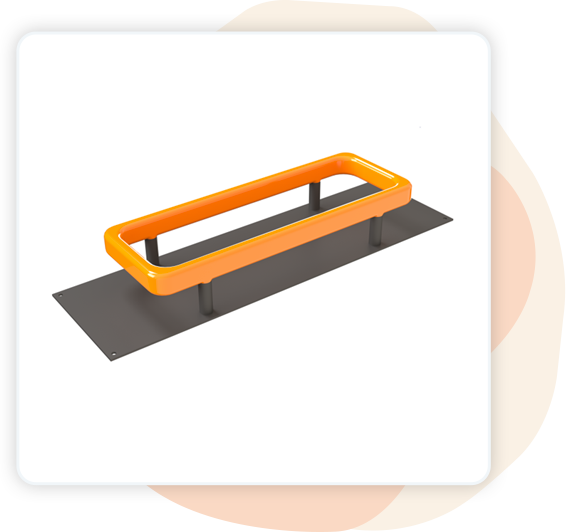

Metal Detector

The metal detector system 3000 is designed to detect medium and large pieces of metal. It can adjust the sensitivity. The metal detector consists of an amplifier and an inductive detector coil. This prevents the metal pieces from entering the crusher. It rings an alarm and stops the feeding conveyor.

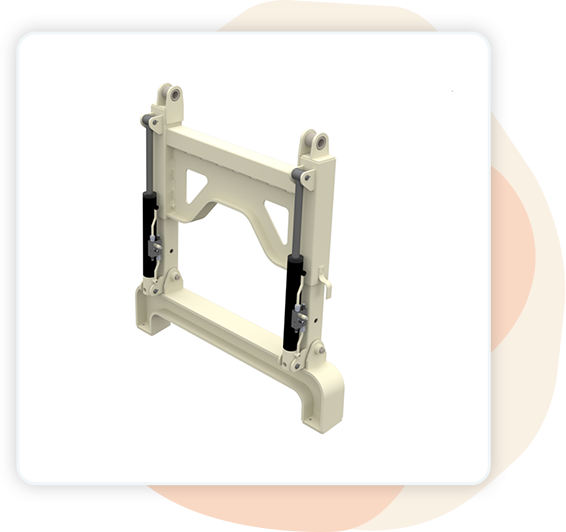

Telescopic Assembly

The telescopic assembly helps in easier transportation. It uses hydraulic principles to lift the equipment for operation and crusher maintenance.

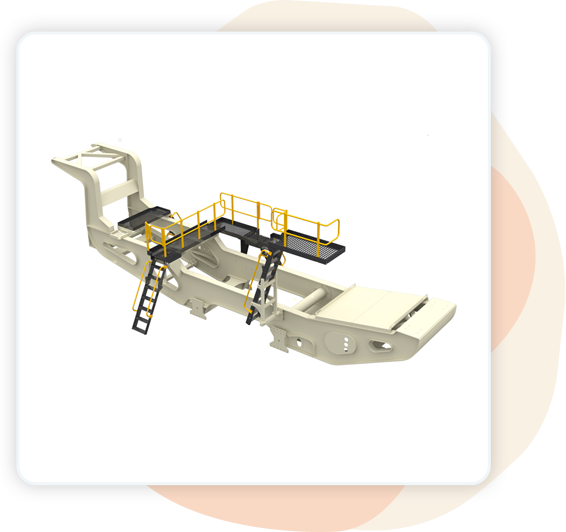

Chassis and Walkway

Heavy duty I-section welded construction provides maximum strength and accessibility to the equipment. The design includes spacious walkway which increases accessibility.

Main Conveyor

The main conveyor consists of a motorized pulley, a nip guide, impact bars at feed point and dust suppression system. It helps to transport material from the cone crusher to the next stage plant. The conveyor is foldable and this aids smoother transportation.

Motorized Pulley

Both the main conveyor and the feed conveyor are attached to the motorised pulley. Upto 95% of the output power produced by the motor is transmitted to the drum shell. It consumes lesser space and is completely protected from water, dust, chemicals, grease and oil.

Engine Package

The engine package includes an engine and an alternator. It powers the entire equipment.

Diesel Tank

Diesel for the engine is stored in the diesel tank, which has a capacity of 500 litres. It has a level sensing device and a filler breather.

Hydraulic Control Unit

The hydraulic control unit provides various pressure levels as per requirement and priority.

The hydraulic control unit provides various pressure levels as per requirement and priority. It generates, adjusts the hydraulic pressure and switches its passage, as per priority. The line pressure control value is governed by a solenoid.

Hydraulic Power Pack

The Hydraulic power pack holds a volume of fluid, transfers heat from the system, allows solid contaminants to settle and facilitates the release of air and moisture from the fluid. The capacity of the hydraulic tank is 400 litres.

Crawler

The undercarriage is the part of a moving vehicle that is underneath the main body of the vehicle. Crawlers are heavy duty machines specifically developed for the transportation and relocation of heavy equipment.

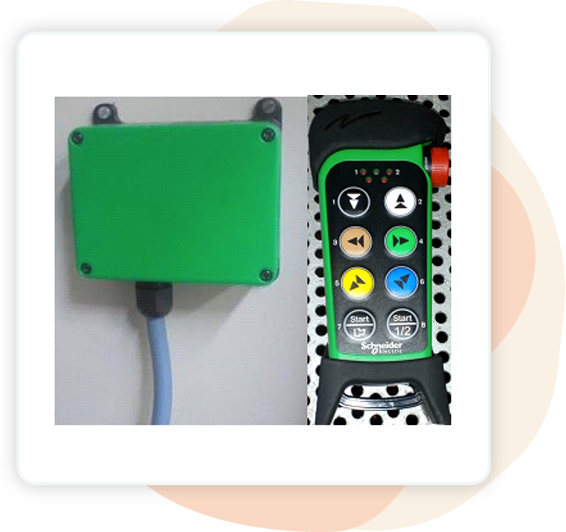

Radio Remote Control

The radio remote controller is used as an application for the movement of the track crawler.

When a command is transmitted from the operator to the receiver located in the control panel, the radio signal is transmitted to 50 m distance around the machine.

Change Over Switch Panel

The change over switch is designed to transfer electricity from the commercial power grid to a local generator whenever outage occurs. Also known as transfer switches, they connect directly to the generator, commercial power supply or line.

Electrical Control Panel (IP55)

The electrical control panel is designed with a double door which makes it dust and water proof. It has IP55 certification and is mounted in the machine. The machine is controlled through electrical operation via the operating panel. While the operation happens in manual mode, the panel is operated through auto mode functions. Illuminated push buttons makes the manual operation easier. Auto mode operation is controlled by the HMI display.

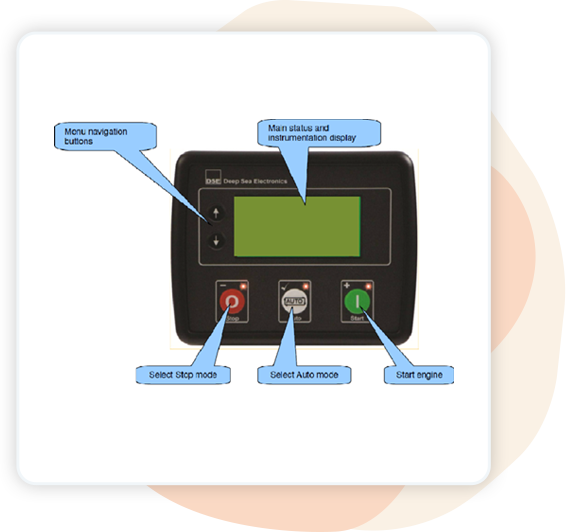

Engine Controller (DSE4520 SERIES)

As the name suggests, the engine controller device controls the engine start/stop. Electrical parameters, which have been set as per our applications, is shown in the display.