How to improve the performance of crusher’s lubricating system?

Productivity Enhancement | November 4, 2020

Maintenance of the machine increases its productivity and in turn its life time. This also implies that every part of the machine must be maintained for a trouble-free operation. Experience has revealed that using recommended oil as per the scheduled maintenance is good for the crusher.

NEGLIGIENCE OF LUBRICATIING SYSTEM MAINTANENCE

INFILTRATION OF FOREIGN PARTICLES INTO LUBE UNIT

CONTAMINATES THE OIL

CONTAMINATED OIL FLOWS OVER BEARING SURFACES OF THE CHAMBER

RESULTS IN SEVERELY WORN COMPONENTS AND BEARING CLEARANCES

UNNECCESSARY REPLACEMENT OF COMPONENTS / DOWNTIME

Did you see what negligence can lead to? More expenses and less productivity. This is an undesirable situation. Our team has compiled the steps to be taken to maintain the good health of the crusher’s lubricating system.

Keep an eye on the vital parameters

The oil temperature must be monitored as this can give you a heads up about the health of your machine as well.

A close watch of the oil temperature even between shifts is a tried and tested practice which saves lot of trouble thereafter. Abnormalities can be detected and rectified immediately. The lube oil pressure must also be monitored throughout the shift. To understand what the normal parameters are, watch out for countershaft box oil pressure.

One more aspect to be checked is the oil tank return screen. Regular check of the screen for any unusual material, is a must.

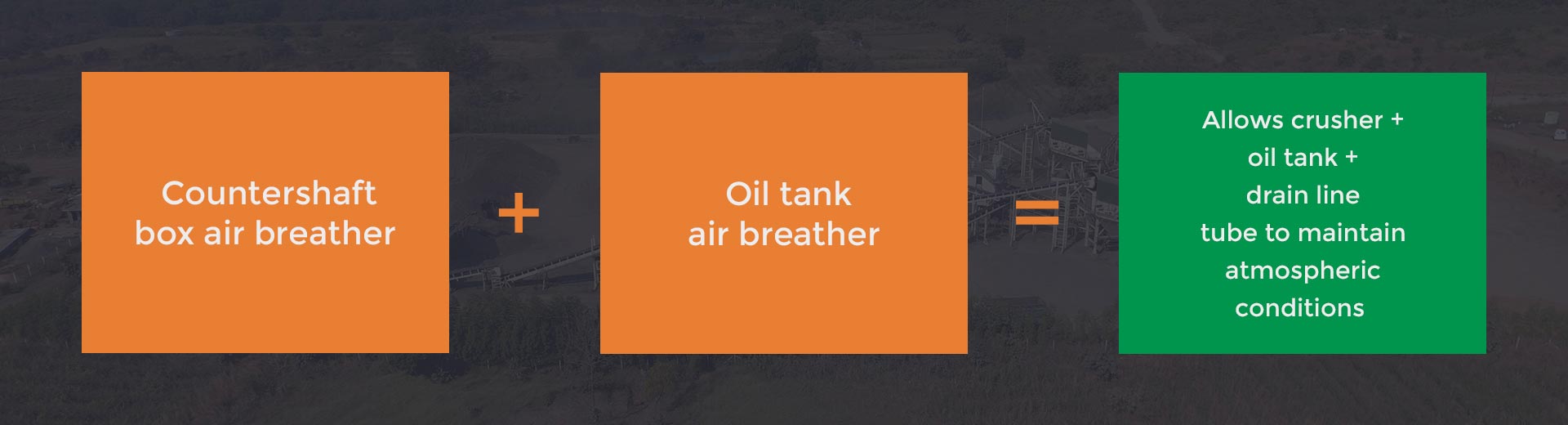

An eye on the crusher air!

Why should air breathers be clean?

- Ensures unrestricted drainage of the lube oil

- Prevents dust infiltration through the head sealing arrangement

Remember

Air breathers should be inspected weekly or after every 40 hours of operation. It should be changed or cleaned as per the requirement.

Put these suggestions to practice and maintain the health of your crusher’s lubricating system.