OPEL – The parent company of Propel Industries

Inside-Out | January 4, 2021

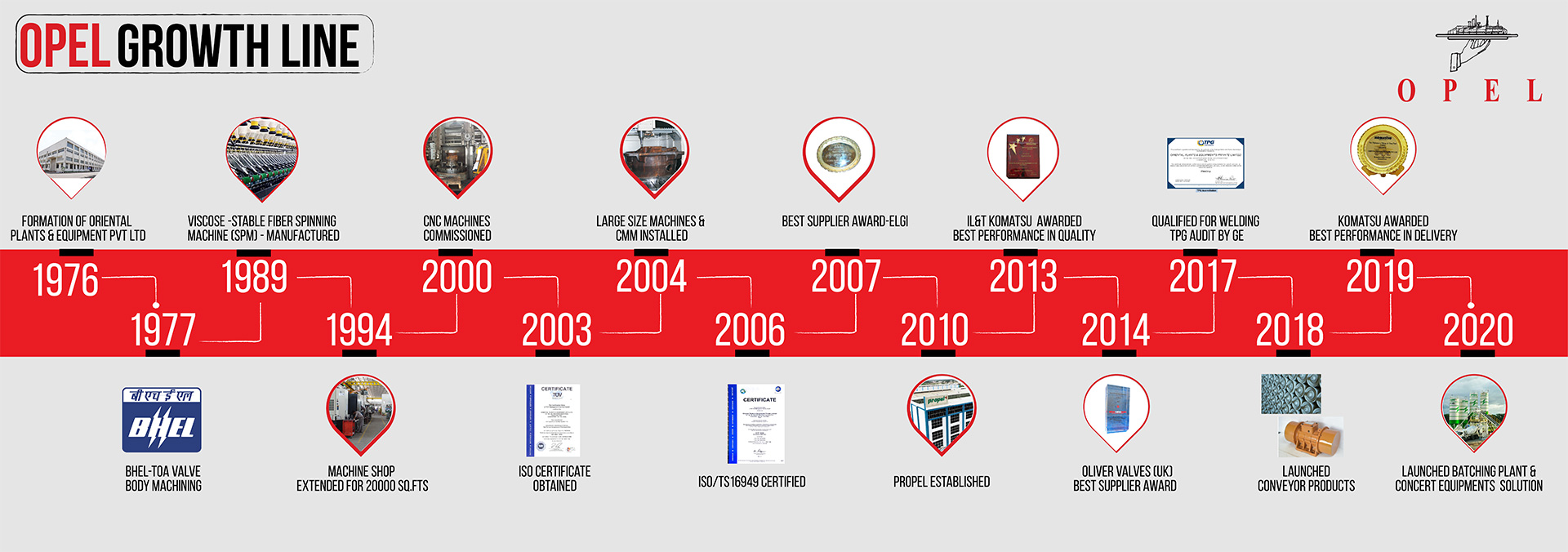

The secret of getting ahead is getting started – This is an old saying which has relevance till date. A good portion of Propel’s success is because the start at ‘Oriental Plants and Equipments Pvt Ltd’ was fantastic.

OPEL is the parent company of Propel Industries Pvt Limited and is growing stronger and bigger with every passing year. OPEL mainly deals with

- Precision Machining Solutions

- Product Solutions

- Conveyor components

- Vibro motors

- Geared motors

- Equipment Solutions

What does OPEL do?

OPEL provides total machining solutions which includes sourcing of raw materials such as castings, aluminium, Iron castings, steel castings, forgings and fabrication for customers across industries.

The industries that OPEL caters to are construction equipment, earth moving machinery, automobile, textiles machinery, wind energy, railway, special valves, defence, mineral processing and petrochemical.

The OPEL infrastructure

1,30,782 sq feet of covered area

63,668 sq feet of uncovered area

Latest equipment

Skilled Workforce

Consistently providing quality products has become the hallmark of OPEL. The integrated machine shop is capable of handling diverse parts from 1 kg TO 10000 KG in weight and 100 mm3 to 4000 mm3 in size.

About the engineering capability….

Opel has

- A focused team for process development

- In-house fixture manufacturing system

- Exclusive project teams for product development

- Separate tool room & CAD center

- Uses software like Solidworks and Edgecam.

Opel has won many awards and accolades from various Original Equipment Manufacturers because of its engineering capability - Komatsu - Best performance in Delivery & Quality for Dump Truck Category (2019-2020) and Komatsu - Best performance for Delivery (2018-2019), being the latest.

Product Solutions

Conveyor components - OPEL has developed world class quality products for conveying applications in aggregates, mining, cement, power & steel industries

Idlers - OPEL supplies Idlers & pulleys for variety of applications in, aggregates, cement, power, paper, sugar, port, steel, foundry.

OPEL Vibro Motors perform well even under demanding conditions. It is well suited for mineral feeding, conveying, screening, de-watering, processing and a variety of other applications.

- User friendly

- Continuously adjustable

- Eccentric weight for efficient operation

(Want to know more about Vibro motor? Read our blog on Vibro Motor)

OPEL Geared Motors has been designed for conveyor drive application, while also keeping the customer needs in mind.

Key features of OPEL Geared Motors -

- Rugged design for conveyor drive applications

- Smooth operation

- Easy installation

- Laminar type self-adjusting sealing arrangement lasts longer even in dusty environment

- The fails-safe cam-clutch type back-stop arrests reverse rotation and ensures higher safety

- Torque 480N to 3.2kN

- Power- 4kw to 18 kw

- Ratios – 13:1 to 30:1

Propel Batching plant

Recently, OPEL extended its engineering acumen to the concrete industry by developing a concrete batching equipment under the Propel brand. The multiple batching solutions from OPEL come with either twin shaft or planetary mixers.

Key advantages of Propel batching plant

- Efficiency in mixing and output

- Robust structure

- Custom-made solutions

- Provides high efficiency and high quality mixing of concrete

- Ease of operation and maintenance

The new generation of batching plant series ranges from 30 m3/H to 120 m3/H per hour.